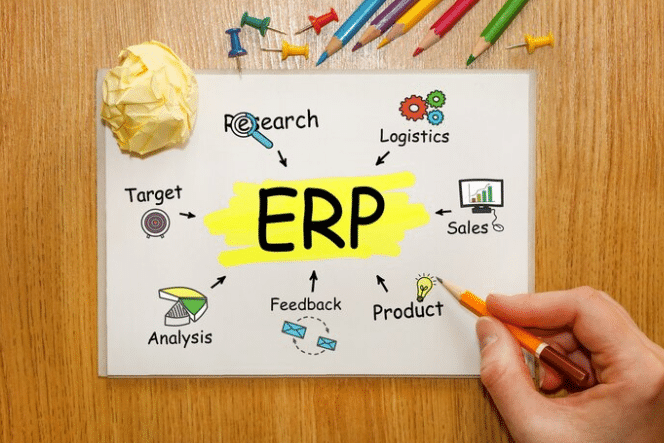

In today’s fast-paced and competitive manufacturing landscape, organizations are constantly seeking ways to enhance productivity, reduce costs, and ensure quality. Manufacturing Enterprise Resource Planning (ERP) software has emerged as a powerful solution to address these challenges. In this article, we’ll delve into the world of manufacturing ERP software, exploring its key features, benefits, challenges, best practices, and real-world applications to provide a comprehensive understanding of how it is revolutionizing the manufacturing industry.

Introduction to Manufacturing ERP Software

- 1.1 What is Manufacturing ERP Software?

Manufacturing ERP software is a comprehensive, integrated system designed specifically for the manufacturing industry. It combines a wide range of functionalities, such as inventory management, production planning, quality control, supply chain management, and financial management, into a single, centralized platform. This system streamlines manufacturing operations, enhances decision-making, and boosts overall efficiency. - 1.2 The Evolution of Manufacturing ERP Software

The development of manufacturing ERP software has evolved from traditional on-premises systems to modern cloud-based solutions. These advancements have made ERP software more accessible, flexible, and capable of addressing the unique challenges faced by manufacturers.

Key Features of Manufacturing ERP Software

Manufacturing ERP software offers a rich set of features that empower manufacturers to optimize their operations:

- 2.1 Bill of Materials (BOM) Management

BOM management allows manufacturers to create and maintain detailed lists of materials and components required for each product, ensuring accurate and consistent assembly. - 2.2 Production Planning and Scheduling

Manufacturing ERP software helps organizations plan and schedule production activities to optimize resource utilization, reduce lead times, and meet customer demands efficiently. - 2.3 Inventory Control

Effective inventory management within the ERP system ensures that manufacturers can track and control inventory levels, minimize carrying costs, and reduce the risk of stockouts. - 2.4 Quality Control and Assurance

Manufacturing ERP systems often include quality control modules to monitor and maintain product quality, reducing defects and improving customer satisfaction. - 2.5 Supply Chain Management

ERP software provides tools to manage the entire supply chain, enabling manufacturers to monitor and optimize the flow of materials and information from suppliers to customers.

Benefits of Manufacturing ERP Software

The adoption of manufacturing ERP software offers a wide range of benefits for manufacturers:

- 3.1 Enhanced Efficiency

By streamlining processes and providing real-time data, ERP software increases efficiency, reduces manual errors, and shortens lead times. - 3.2 Improved Decision-Making

Access to real-time data and analytics enables manufacturers to make informed decisions promptly, whether it’s adjusting production schedules or identifying areas for improvement. - 3.3 Cost Reduction

ERP software helps in cost control by optimizing inventory levels, reducing waste, and streamlining operations. This, in turn, leads to substantial cost savings. - 3.4 Quality Improvement

Quality control features within ERP systems lead to improved product quality, fewer defects, and increased customer satisfaction. - 3.5 Regulatory Compliance

Manufacturing ERP software often includes features to ensure compliance with industry-specific regulations and standards, reducing the risk of non-compliance penalties. - 3.6 Scalability

Manufacturers can scale their ERP systems as they grow, accommodating increased production and expanding operations without the need for a complete system overhaul.

Challenges and Considerations

While manufacturing ERP software offers numerous advantages, manufacturers must also consider potential challenges:

- 4.1 Implementation Complexity

The implementation of ERP software can be complex and disruptive, requiring careful planning and substantial employee training. - 4.2 Cost

ERP software involves upfront costs for licenses, implementation, and hardware. Manufacturers should consider these expenses in their budget. - 4.3 Data Security

Data security is a critical concern, as ERP systems contain sensitive information. Manufacturers must implement robust security measures and data backup strategies. - 4.4 Integration

Integrating ERP software with existing systems and equipment can be challenging. Custom integration solutions may be necessary to ensure seamless operation. - 4.5 Change Management

Adopting a new ERP system can be met with resistance from employees. Effective change management strategies are crucial to ensure successful implementation and user adoption.

Best Practices for Manufacturing ERP Software Implementation

Implementing manufacturing ERP software requires careful planning and execution. Here are some best practices:

- 5.1 Define Objectives

Clearly define the objectives you aim to achieve with the ERP implementation. Understand what specific processes and areas need improvement. - 5.2 Choose the Right ERP System

Select an ERP system that aligns with your manufacturing needs, whether you’re in discrete manufacturing, process manufacturing, or a hybrid of both. - 5.3 Plan Thoroughly

Develop a comprehensive implementation plan that covers every aspect of the transition, from data migration to employee training. Ensure you have the necessary resources and personnel. - 5.4 Data Quality and Security

Prioritize data quality and security. Regularly back up data and implement strong security measures to protect sensitive information. - 5.5 Ongoing Training and Support

Provide ongoing training for employees to ensure they can use the system effectively. Additionally, establish a system of support for troubleshooting and maintenance.

Real-World Applications of Manufacturing ERP Software

Let’s explore how manufacturing ERP software is making a difference in the manufacturing industry:

- 6.1 Aerospace: Boeing

Boeing, a leading aerospace manufacturer, utilizes manufacturing ERP software to streamline its complex production processes. The software helps in managing the extensive BOMs and intricate supply chains associated with aircraft manufacturing. - 6.2 Food Processing: Nestlé

Nestlé, a global food and beverage company, relies on ERP software to ensure quality and compliance in food processing. The software manages production schedules, inventory, and quality control processes across its vast range of products. - 6.3 Automotive: Toyota

Toyota, a renowned automotive manufacturer, leverages ERP software to optimize production efficiency. The system enables Toyota to manage inventory levels, reduce lead times, and respond swiftly to changing market demands.

The Future of Manufacturing ERP Software

The future of manufacturing ERP software holds exciting possibilities:

- 7.1 IoT Integration

Manufacturing ERP systems will increasingly integrate with the Internet of Things (IoT) to collect and analyze data from sensors and devices, enabling predictive maintenance and improved decision-making. - 7.2 Artificial Intelligence (AI)

AI will play a more prominent role in manufacturing ERP, offering predictive analytics, demand forecasting, and process automation to enhance operational efficiency. - 7.3 Cloud-Based Solutions

The adoption of cloud-based manufacturing ERP solutions will continue to grow, offering flexibility, scalability, and easy access to real-time data.

Conclusion

Manufacturing ERP software is a vital tool for manufacturers seeking to optimize their operations, reduce costs, and enhance product quality. While challenges such as implementation complexity and cost exist, the benefits of ERP software are substantial. As technology continues to advance, manufacturers that embrace manufacturing ERP software are well-positioned to compete effectively in the global market and ensure their place at the forefront of the manufacturing industry